West System Slow Hardener Cure Time

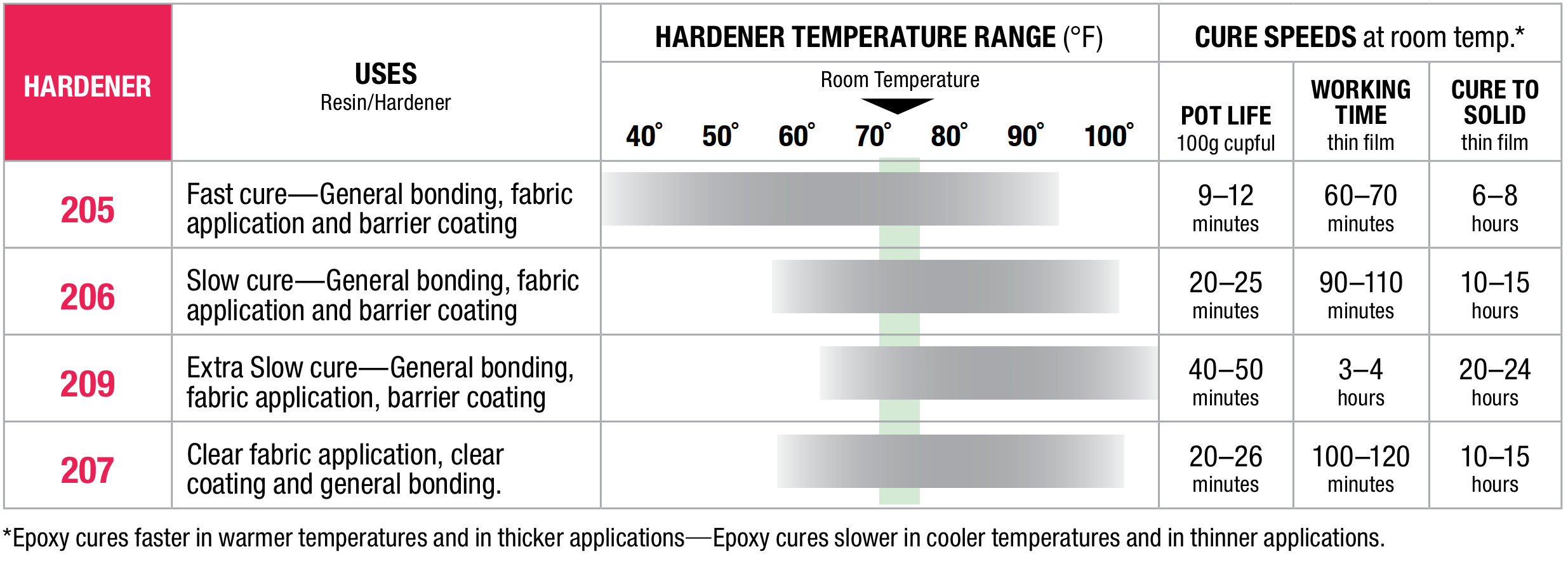

West system slow hardener cure time. It is important to select the hardener that gives you adequate working time for the job you are completing. Slow Hardener by West System. Check correct number of pump strokesuse equal strokes of resin and hardener.

When combined with 105 Epoxy Resin in a five-part resin to one-part hardener ratio the cured resinhardener mixture yields a rigid high-strength moisture-resistant solid with. At 72-degrees 206 Slow Hardener will have a 20-25 minute pot life. Here is what you need to know to ensure adequate working time when using epoxy in warm conditions.

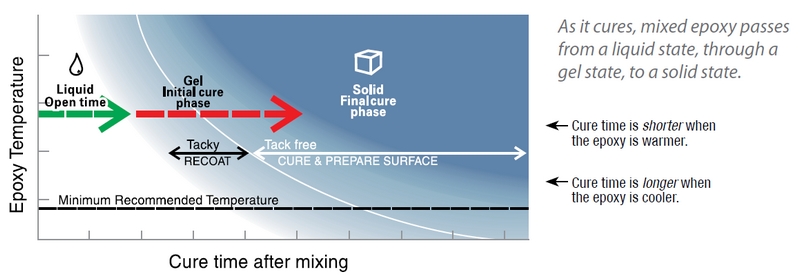

At any given temperature a mix of each of these hardeners with 105 Resin will go through the same cure stages but at different rates. Epoxy cures faster in warmer temperatures and in thicker applications. 205 Fast Hardener is not intended for clear coating.

Sizes 207 ml Group Size A 814 ml Group Size B 358 L Group Size C Sold Since. Adjust the viscosity of the resinhardener mixture by the amount of filler added. 10 to 15 Hours Working.

Adjust the strength weight texture sandability and color of the cured epoxy with one of six West System Fillers. Off ratiotoo much or too little hardener will affect the cure time and thoroughness of the cure. If you are purchasing a 40 litre container please contact us for a.

Ensure you have enough working time. Cured resin and hardener yields a rigid high-strength moisture-resistant solid with excellent bonding and coating properties. Cure to working strength.

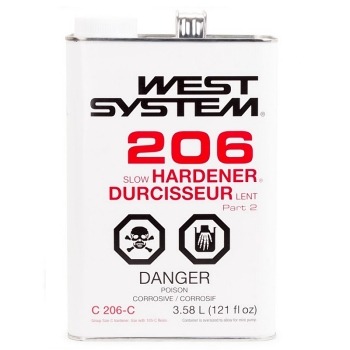

If the weather is either too cold damp or too hot and dry. 206 Slow Hardener is used when extended working and cure time is needed or to provide adequate working time at higher temperatures.

Slow Hardener by West System.

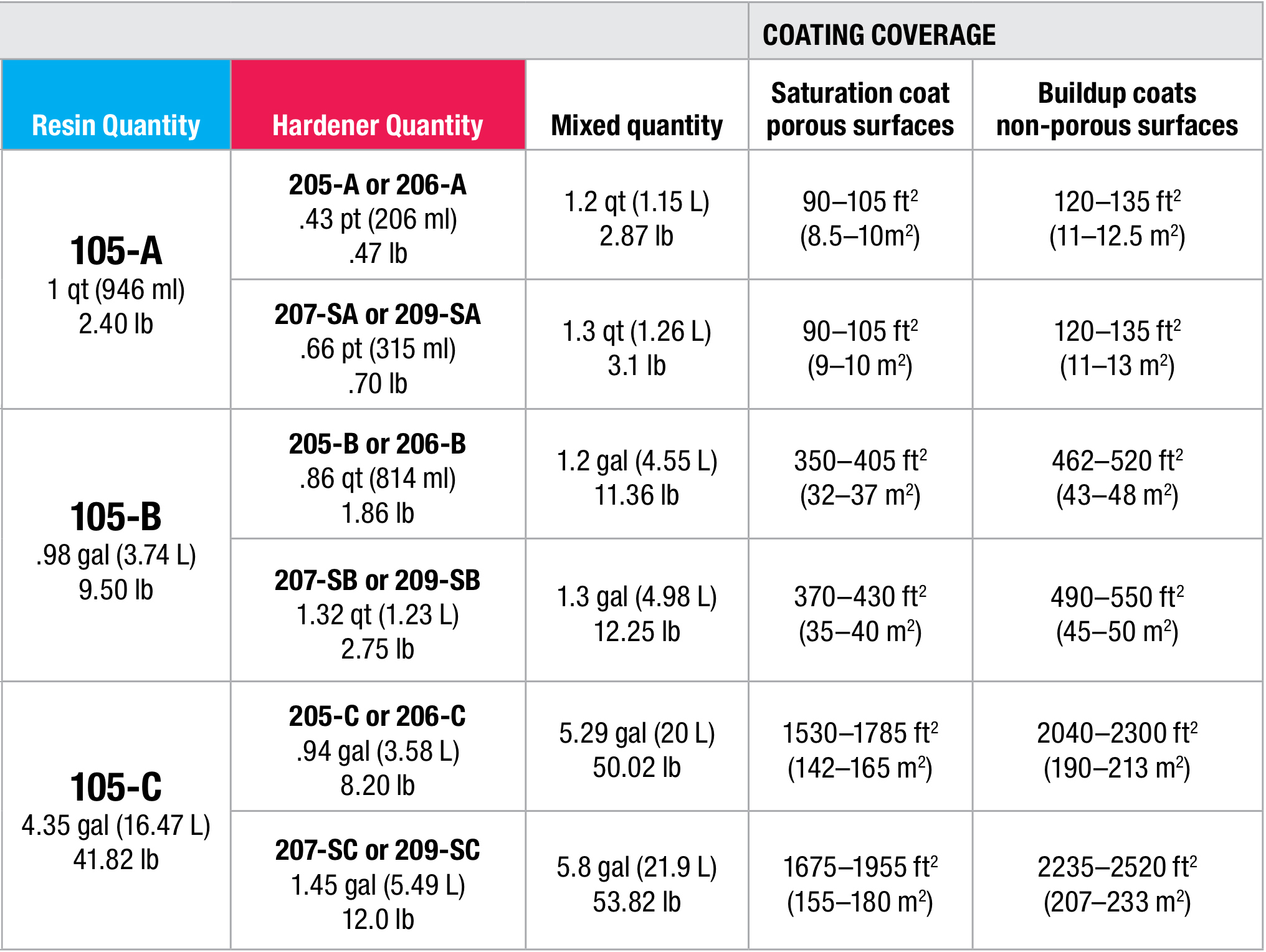

Adjust the strength weight texture sandability and color of the cured epoxy with one of six West System Fillers. Cure to a solid state. 206 Slow Hardener is a low-viscosity epoxy curing agent. WEST SYSTEM 206 Slow Hardener is a low-viscosity epoxy curing agent. Do not apply additional material over non-curing epoxy. 1 to 4 days. Epoxy cures faster in warmer temperatures and in thicker applications. WEST SYSTEM 206 Fast Hardener is available in 100ml 200ml 800ml 4 litre and 40 litre packs. Mix it with WEST SYSTEM 105 Resin in a five-part resin to one-part hardener ratio.

The combination of 105 Resin205 Fast Hardener has excellent bonding and coating properties. Cure to working strength. 209 Extra Slow Hardener mixed at a 31 ratio with 105 Resin results in a pot life of 20-25 minutes at 72F with 10-15 hours required for a solid cure. At any given temperature a mix of each of these hardeners with 105 Resin will go through the same cure stages but at different rates. All assembly and clamping should take place during the open time to assure a dependable bond. Adjust the strength weight texture sandability and color of the cured epoxy with one of six West System Fillers. 1 to 4 days.

Post a Comment for "West System Slow Hardener Cure Time"